Anyone who does woodworking for a living or fun should have a circle saw. It is a must-have in any workshop because it can be used on many different materials and make accurate cuts.

But it is very important to store the circular saw correctly when not in use to make sure it lasts a long time and is safe. This piece will talk about the best ways how to store circular saw and keep it in good shape so that they work at their best.

Putting away your circular saw the right way keeps it safe from damage and out of reach of kids or other people who might use it incorrectly. There are a few easy things you can do to keep your circle saw in good shape and ready to use whenever you need it.

In the parts that follow, we’ll talk about different ways to store a circular saw, such as safety precautions, cleaning, and maintenance, storing the blade and cord, making adjustments and making sure they are secure, removing dust, and carrying and transporting the saw.

These tips will help you keep your circle saw in great shape and make it last longer.

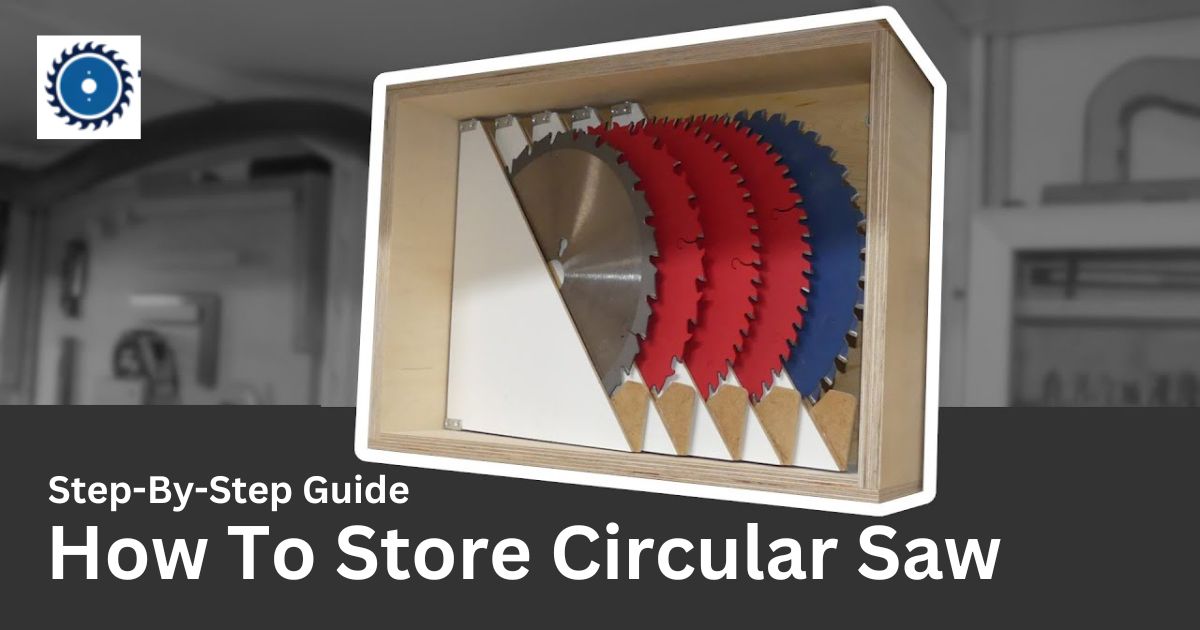

Best Storage Ideas for Your Circular Saw and Blades:

Not sure what to do? If you want to make a safe and good place to store your circle saw, here are some ideas.

1) Case:

If you want to protect your saw, the best case has sides that are made to hold the tool in place. Some can even take shocks. If you already have the original carrying case, it will work.

2) Shelves:

Having shelves is great because they are easy to get to. Most shelves are open and connected to the wall. You can decorate your wall with it and keep your saw blades in order with all the creative options it gives you.

3)Rack Attached to the Wall:

Racks are open and hung on walls, like shelves. But they are usually stronger and have more levels and sections, which makes them easier to organize and get to tools.

4) The Cabinet:

Because it’s closed off and can’t be moved, putting tools in the closet keeps them safer than other places to store them. When you put knobs on cabinet drawers in the right place, they stay in place and save a lot of room.

5) Make Your Storage Holder:

Having storage holders that are made just for you lets you put away your saw in the most handy way for you. This can save you money if you’re creative.

6) A Box For Your Blades that Looks Like a CD:

This type of storage works a lot like CD storage. It’s a small, movable way to keep your blades in order.

7) A Knife Block to Hold the Blades:

Putting blades into grooves on a knife block is a good way to store them, especially after sharpening a circle saw blade. This way of keeping blades makes it easier to get one when you need it.

8) Magazine Rack with Blades:

Magazine blade racks are the same as book and magazine racks. They are usually made of wood, though, and have holes for the blades to fit in. The great thing about this choice is that it’s portable—the rack can be moved to any location that works best for you.

Making a DIY Circular Saw Storage Holder:

You only need a few easy cuts, some common woodworking tools, and some scrap wood to make this handy rack.

Which kind of wood should you use?

You can use almost any kind of wood to make this storage box. It’s easy to make this project with little wood, so it’s a great way to get rid of old wood.

Step 1) Prepare the Sides:

For the ends, cut three pieces of wood to the right length.

Measure in and make a mark on one end. Join the mark to the corner with a pencil.

To cut the side, you can use a circle saw or a crosscut jig. You can put double-sided tape on the part of the board that will be the side because there isn’t enough flesh on the board to clamp the crosscut jig. To put it another way, you can stick the tape on the piece you want to keep.

After that, you can take the tape’s back off, put the jig on the line, and push it into the tape.

You can use the circular saw to cut and do the same thing for the other side pieces as well.

Step 2) Assemble the Left Side:

Next, put together the left side. For the left face, cut one piece of wood to the right length. After that, use the picture on the printed plan to mark where the countersink holes will go.

Make a hole for the drill bit to start in with an awl.

Then, drill countersink holes in each mark with a countersink drill bit. The curved sides can be hard to clamp to the face. Clamp a piece of scrap wood to the inside of the side instead, then glue it and clamp it to the face. Use 1-¼” wood screws to attach.

Put glue on the outside of the side that faces the blade, clamp a piece of scrap wood to it, and then clamp it to the face. Use 1-¼” wood screws to attach.

Step 3) Assemble the Right Side:

For the right face, cut one piece of wood to the right length. After that, use the picture on the print plan to mark where the countersink holes will go.

Make a hole for the drill bit to start in with an awl.

Then, drill countersink holes in each mark with a countersink drill bit.

The curved side can be hard to clamp to the face. Put glue on a piece of scrap wood and clamp it to the inside of the side again. Then clamp the scrap wood to the face. Use 1-¼” wood screws to attach.

Step 4) Put the Stretcher Cut on:

Cut a piece of wood to the right length for the stretcher and drill holes in both ends for pockets. Put glue on the ends, put it on the back, and clamp it in place. Use 1-¼” pocket screws to attach.

Step 5) Put the Cleat on:

To make the cleat, cut a piece of wood to the right length. Use the picture on the printed plan to figure out where the countersink holes should go.

Make a hole for the drill bit to start in with an awl.

Then, drill countersink holes in each mark with a countersink drill bit.

Put the clamp and cleat in place. Use 1-¼” wood screws to attach.

Step 6) Extra Items:

If the cleat is hit by the bolt that lets the base plate of the circular saw bevel. The saw can’t rest straight up and down because of this. As a stop, add a simple piece of old wood. Make a countersunk hole in the middle, and use a wood screw to it to the holder.

For some circle saws, this holder’s angle might be too steep, which can

let the saw fall out of the holder. In this case, you can use scrap wood to add a simple lock.

There should be a little more space between the bottom layer of the lock and the base plate. The lock can be almost any width.

Start by drilling a hole in both parts of the lock. Then, use a wood screw to connect them to the holder. The screw should be tight, but the lock should still be able to turn.

Safety Precautions:

To protect your health and the health of others, it is important to talk about some safety measures. If you don’t know how to use a circular saw properly, you could seriously hurt yourself. Remember these safety tips:

- When using or handling a circle saw, you should always wear the right personal protective equipment (PPE), like safety glasses, earplugs, and gloves. This will keep you safe from moving objects and lower your risk of getting hurt.

- Make sure the saw is turned off and unplugged before you store or do any repair on it. If the saw is turned on by accident, it can cause serious damage.

- To use the saw, keep your hands away from the blade and any moving parts. When the blade is moving, you should never reach under it.

- Make sure the piece of work is properly secured so it doesn’t move or shift while it’s being cut. This will cut down on kickbacks and improve the accuracy of cutting.

- Always follow the directions and notes that came with the saw from the manufacturer. There may be different safety rules and suggestions for each type of saw.

- When not in use, put the circular saw away in a locked cabinet or a place where children and other unwanted people can’t get to it.

- Always check the saw for any broken or loose parts, like guards that aren’t attached properly or a blade that is too worn out. If you find any problems, fix or replace the parts of the saw before you use it again.

- While the saw is still on, do not leave it unsupervised. If someone comes into contact with the spinning blade by mistake, this could be dangerous.

- To cut properly, you should learn things like how to keep your balance and how to use both hands to handle the saw. This will help make mistakes less likely.

If you take these safety steps, you and everyone else around you will be safe while using a circle saw. Safety should always come first, and you should never skimp on taking the right measures.

Cleaning and Maintenance:

Cleaning and maintaining your circular saw the right way is important for making sure it lasts as long as possible and works at its best.

By giving the saw regular care, you can keep dust, dirt, and other harmful substances from building up and making it less useful. Keep things clean and in good shape with these tips:

- Check the saw for dust or other debris every time you use it. Get rid of the dust on the blade, guard, and other parts with a soft brush or compressed air.

- Look for damage on the blade, like teeth that are missing or broken. If you need to, replace the blade to make sure the cuts are clean and precise.

- Check to see if the motor brushes are worn out. If the brushes are worn out, you should change them so that the motor stays in good electrical contact.

- Keep the moving parts, like the blade guard, adjustment knobs, and tilt system, oiled all the time. Use a lube that was suggested to make sure everything works smoothly.

- Look for signs of damage on the power cord, like fraying or wires that peek out. If the wire is broken, you should replace it before using the saw again.

- Keep the saw away from anything dirty or wet. Rust and other problems with the saw’s parts can be caused by water.

- If the dust collection bag on your circle saw needs to be cleaned or replaced often, do so. If the dust bag gets clogged, it can make the extraction device work less well.

- Check the safety features, like the blade guard and the system for adjusting the blade’s depth, to make sure they are working properly.

- Check the circular saw’s owner’s manual to see if there are any special maintenance needs or suggestions.

By cleaning and maintaining your circular saw in this way, you can keep it in great shape and make sure it works well when you need it to.

Blade Storage:

To keep your circular saw blade in good shape and for a long time, you need to store it correctly. A safe and secure place to put the blade when not in use is important to avoid any damage or accidents. Here are some ways to store blades:

- When you are done using the saw, take the blade off. This keeps them from touching by mistake and lowers the chance of getting hurt.

- Before putting the blade away, clean it very well. Do not leave any buildup or residue on the blade. Instead, use a blade cleaning solution or a light detergent. Before putting it away, make sure it’s completely dry.

- To keep the blades safe and organized, you might want to use a blade storage bin or a blade rack. These bins can be used to store blades in a safe and organized way.

- Check to see that the case for storing the blades is clean and free of any dirt or water. If the blade gets wet, it can rust or damage the carbide teeth.

- Do not put the blade away in a drawer or anywhere else where it might touch other tools or things that could hurt it.

- To give the blade even more safety, you might want to use blade protectors or blade sleeves. When you handle or store the blade, these can keep you from cutting yourself or nicking it by chance.

- Write the blade’s diameter and tooth count on the blade storage bin or blade sleeves so that it’s easy to find when you need it.

- The blade should be kept somewhere cool and dry, out of direct sunlight, and away from high temperatures. This helps keep the quality and edge of the blade.

- Check the blade for any signs of damage or wear before putting it back on the saw. If there are any problems, you should get a new blade before using the old one again.

Store your circular saw blades in this manner to keep them in good condition and ready to use.

Keeping blades properly prevents accidents and makes handling them safer.

Cord Retention:

The power wire for your circular saw should be stored properly to keep it from getting tangled or damaged and to make sure it lasts as long as possible. Here are some ways to store cords:

- Unplug your circular saw from the power source before putting it away. This keeps everyone safe and stops the saw from starting by chance while the cord is being handled.

- Do not wrap the power line too tightly around the saw or anything else. This can put stress on the lines, damaging them over time. To avoid kinks and tangles, use an open coil or figure-eight coil method instead.

- To keep the cord tightly wound and safe, you could use cord wraps, cable organizers, or Velcro straps. These add-ons help keep the cord from coming apart or getting mixed up with other parts or tools.

- Put the length of the cord on the cord wrap or storage bin so it’s easy to find.

- Keep the cord somewhere dry and clean, away from water, sharp items, and very hot or very cold temperatures. Wetness can harm the electrical parts, and sharp items can cut or poke holes in the cord.

- Check the power cord often for damage signs like breaking, wires that are showing, or connections that aren’t tight. If the cord is broken, fix it or get a new one before using the saw again.

- Keep heat sources, chemicals, and oils away from the power cord. These things can damage or wear down the insulation on the cord.

- Do not yank or pull the line from far away to disconnect it from the power source. This could put stress on the cord and its links. Instead, use the plug to gently unplug the line to keep it from breaking.

- Make sure to safely tie down the cord when moving the saw so that it doesn’t get tangled up or broken.

Following these guidelines for cord storage will ensure that your circular saw’s power cable remains in excellent condition, extending its life and reducing the risk of injury.

Modifications and Securing:

It is vital for the precision and security of your circular saw operation that it be adjusted and secured appropriately.

It is crucial to adhere to the instructions and guidelines provided by the manufacturer when making adjustments to the bevel angle or cutting depth.

The following are some suggestions for securing and adjusting your circular saw:

- Read the saw’s handbook to learn about its adjustments. Different saws may have different bevel angles, cutting depths, and other adjustments.

- Always disconnect and power down the saw before making modifications. This prevents accidental saw use, reducing injury risk.

- When changing cut depth, account for workpiece thickness. This ensures that the blade penetrates the material to the desired depth, resulting in clean, precise cuts.

- Use saw manufacturer scales, indications, or measurements for correct adjustments. This helps achieve cutting goals and consistency.

- Once alterations are made, tighten adjustment knobs or levers. Preventing movement during operation ensures consistent settings.

- Check and adjust the saw bevel angle for angled cuts. A protractor or bevel gauge ensures accurate and uniform bevel adjustments.

- Press the saw’s base or shoe on the workpiece for stability and reduced vibrations. This speeds cutting and ensures perfect slices.

- Make sure all adjustments are set and secured before sawing. This includes checking the bevel angle, cutting depth, and other settings.

- Watch for adjustments made while using them. Pause the saw and inspect for misalignments or loose pieces if you find any issues.

- Regularly check the saw’s mechanics and settings for damage, wear, and looseness. Repair or replace damaged parts to maintain saw performance and safety.

Adequate adjustment settings and secure fastenings serve to enhance the quality of incisions and reduce the likelihood of accidents occurring during operation.

Extracting Dust:

Dust extraction helps keep a circular saw workspace clean and healthy. Cutting dust and debris can injure the saw and be inhaled. Effective dust extraction tips:

- Check your circular saw’s dust extraction mechanism. Many modern saws have a port or attachment for dust collecting.

- Use a vacuum, dust bag, or sawdust extractor. To collect saw dust, attach the right equipment to the dust port or attachment.

- Empty and clean the dust collection bag or vacuum periodically for maximum performance. Filled dust collectors are less effective.

- Take dust from the saw by placing a dust collector or vacuum near the cutting region. This reduces airborne dust and cleans the workspace.

- Use a dust shroud or DIY enclosure around the cutting area to route dust to the dust extraction system. This reduces dust and boosts extraction efficiency.

- Protect yourself from airborne dust by wearing a dust mask or respirator. Working in enclosed locations or with plenty of dust requires this.

- To avoid dust extraction system blockages, clean the saw’s dust port or attachment regularly. Remove dust and dirt with a brush or compressed air.

- Consider a dust control system with air filtering and extraction. This reduces workplace dust and improves air quality.

- To disperse dust when working outdoors or in a well-ventilated location, open windows or utilize fans.

- Use dust extraction devices with your circular saw safely and effectively by following the manufacturer’s instructions.

These dust extraction tips can make your cutting process safer and more efficient while extending the life of your circular saw.

Carry and Transport:

To protect your circular saw and stay safe when traveling, carry it properly. Here are some suggestions for safely transporting your circular saw to a job site or workshop:

- Turn off and unplug the saw before handling it. Accidental saw activation is prevented, reducing injury risk.

- To balance and manage the saw, grab the handle tightly. Keep fingers away from blades and moving parts.

- Consider a circular saw bag or carrying case. This adds protection and convenience, especially while moving the saw.

- Always shut and secure the carrying case or bag before lifting or transporting it. It keeps the saw from dropping out or moving during shipment.

- Keep the saw in a separate storage room when carrying it in a vehicle. Strap or bungee it to avoid sliding during transport.

- Avoid transporting large objects on the saw, since they might harm the blade, motor, and other parts.

- Use safe lifting techniques to avoid back and muscular pain when loading or unloading the saw from a vehicle. While maintaining your back straight, bend your knees and lift the saw.

- Consider disassembling the saw if you need to travel it far. For safety, remove the blade and accessories and stow them.

- Consider the saw’s weight and dimensions to ensure you can carry it without straining or dropping it.

- Be careful not to trip or bump into objects when carrying the saw on foot. Beware of obstacles and uneven surfaces when transporting the saw.

Follow these carrying and traveling suggestions to keep your circular saw in good shape. Transporting the saw safely extends its longevity and prevents injury.

Bottom Line: How To Store Circular Saw Blades

How to Store a Circular Saw for repair affects its lifespan. These instruments are useful and can help you manufacture items worth many times their cost, so take care of them.

Take precautions when using and storing your circular saw. Always use safety gear, turn off the saw, and keep youngsters and others away.

Regularly cleaning and maintaining your circle saw keeps it in good condition. Clean the saw after each use, check for damage, and oil the moving components as required.

Blades must be stored properly to avoid damage and collisions. Clean the blade before storing. Guard or cover the blade and keep it dry and clean.

Cords are less likely to get broken or knotted when stored carefully. Cord wraps or organizers make electricity lines tidy and safe.

Make sure your circular saw is properly set up and its pieces are securely fastened.

Check and adjust cutting depth, bevel angle, and other parameters regularly to ensure accuracy and consistency.

The workplace needs good dust clearing to stay clean and healthy. Use dust collectors or vacuums to remove cutting dust, and wear safety gear to avoid inhaling it.

When moving your circular saw, turn it off and hold it by the handle. A packing case or bag and tie-down while moving the saw can prevent damage or mishaps.

These best practices for storing, maintaining, and moving your circular saw will extend its life, improve its performance, and keep you and others safe. A well-maintained circular saw will endure many projects.

FAQs

What Are The Most Effective Storage Methods for a Circular Saw?

It is ideal to remove any sawdust or debris from a circular saw by performing a comprehensive cleaning following each use before storing it. After that, place it in an area that is dry and well-ventilated to prevent oxidation and corrosion.

Additionally, a protective case or cover should be utilized to safeguard it against potential injury.

How Should I Keep My Circular Saw in Good Condition While in Storage?

To keep your circular saw in good condition during storage, check for symptoms of wear and tear such as loose parts or dull blades regularly.

It’s also crucial to keep the saw oiled and check the power cable for any damage. Also, make sure to store it somewhere where it will not be exposed to excessive temperatures or dampness.

Can I Hang My Circular Saw on the Wall as Storage?

Yes, you can hang your circular saw on the wall for storage, but do so safely. To avoid mishaps, use a solid hook or hanger built exclusively for power tools and ensure that the saw is securely attached.

Hanging the saw can also conserve space and make it more accessible for future usage.

Related Posts: