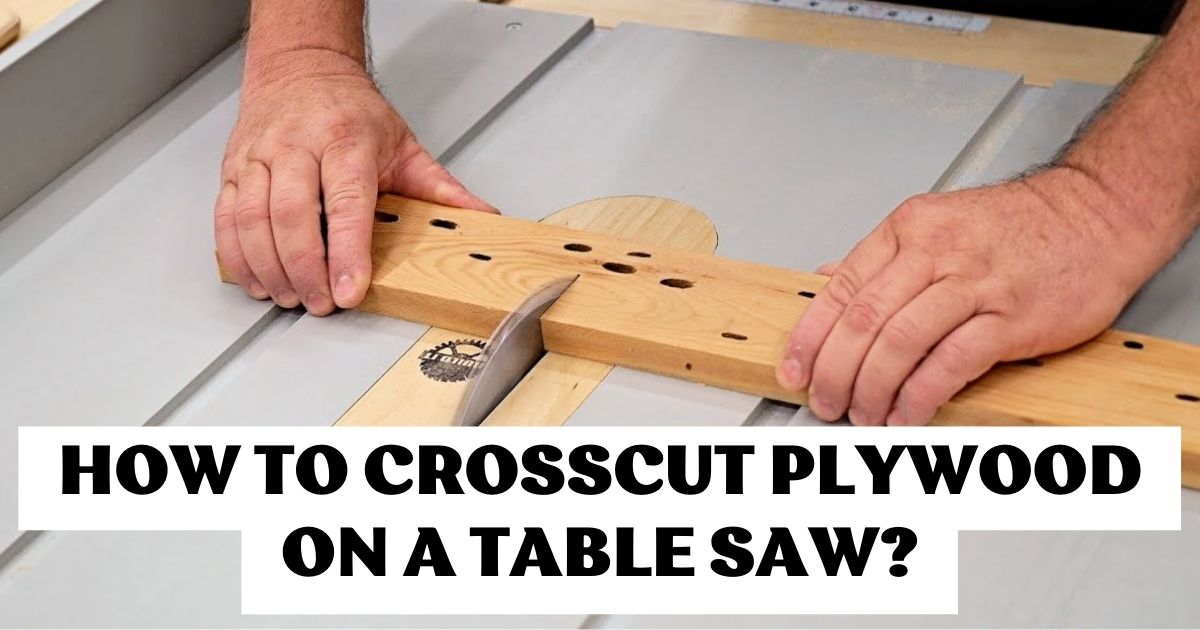

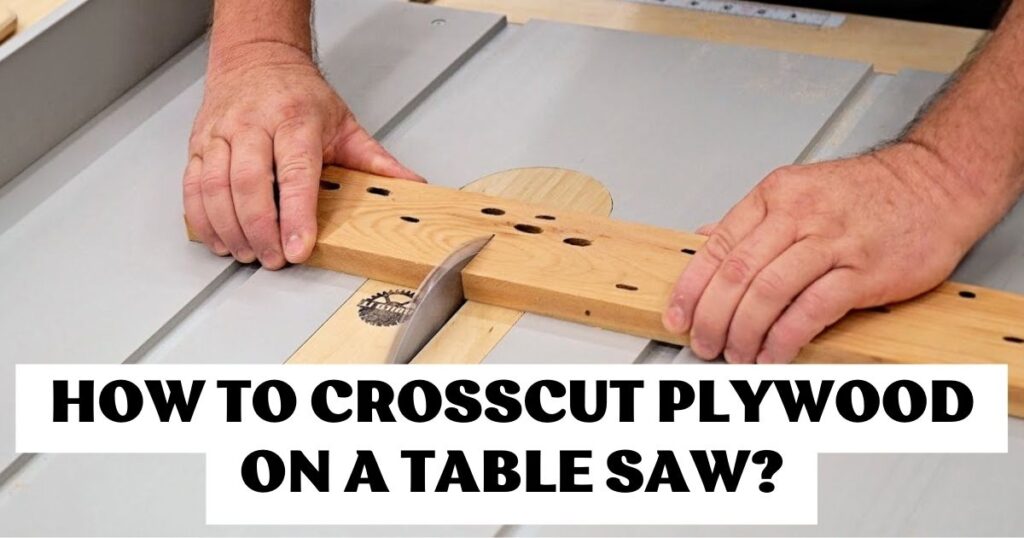

It takes more work to cut hardwood because it is laid out in layers. If you want a good finish, you need to know how to use a table saw to cut plywood.

Cutting big sheets of plywood with a table saw can be awkward and fall over. But there are a few things you can do to make cutting plywood sheets faster, more accurate, and with less chipping. For example, if you want parts that are free of chips, you should get the right table saw.

In this article, we will guide you through the process How to Crosscut Plywood on a Table Saw, step by step. We’ll cover everything from setting up your saw to choosing the right blade and ensuring your safety. Let’s get started!

For what Reason Would you Use a Table Saw?

Cutting across the grain of the wood is what it means to crosscut. Most of the time, this means cutting plywood and other rectangle boards on the short side instead of along their length, which is called a rip cut. It’s important to note that a miter cut will give you a smaller slope than a crosscut or rip cut when you’re done.

You can make your crosscut with a number of different power tools, but table saws are better than jigsaws and even skill saws in a number of important ways:

- For more stability

- Much more accurate

- Better cutting speed and longer blade life

You will be able to make better, cleaner cuts with all of these things. This will take your woodworking to the next level. Remember that jigsaws are much safer than table saws and even skill saws are less likely to cause accidents. Always follow the safety rules and wear the right safety gear when using your table saw.

A Comprehensive Guide: How to Crosscut Plywood on a Table Saw:

Here’s a step-by-step guide on how to crosscut plywood on a table saw:

Step 1) Choose the appropriate blade:

If you want to use a table saw to cut plywood perfectly straight, you will need to buy a special blade with a lot of teeth. For example, an 80 TPI saw blade for plywood has 80 teeth per inch.

The “native” table saw blades are mostly only good for rough cuts and won’t give you smooth lines.

You don’t have to buy a saw blade to cut plywood. Instead, you can put a gap-free saw plug under it. To make it, just carefully put a whole sheet of plywood on the table while the saw is running. Watch out that the plywood doesn’t slip or fall off.

Once the table saw’s blade is raised high enough to cut through the plywood all the way, use a vice to hold the cut sheet in place on the table.

The bottom of the sheets that have been cut on a table saw will no longer split if you make your own plate. This is because there will be no space between the table saw and the saw hole in the table.

To get the job done right, you have to damage one sheet of plywood. This makes sense if you need to cut a lot of plywood.

The blade on your table saw will be very sharp after you follow this step-by-step guide!

Step 2) Make sure the blade is clean:

To begin, make sure the table saw blade is always clean and shiny. Rust and other debris can make the boards hard to cut because they cause friction. When you rip, you move the blade along the wood’s grain. A cut through the grain is called a cross-section.

There is no one-grain direction in plywood because it is made of many layers of wood that are glued together, with each layer generally being at right angles to the next. A rip cut would be used to get the length right, and a cross-cut would be used to cut.

Step 3) Raise the blade of the table saw to cut right:

When you raise the blade, the teeth will go into the plywood in a different way. The teeth enter the board at an angle when the blade is raised just enough so that they barely touch the surface.

It’s possible to get a perpendicular cut by raising the blade a little higher. This will make the surface of the board smoother.

The blade of the table saw should not be raised more than 1 inch (2.5 cm) above the board that you want to cut. It is safer to use a raised blade, but it can make the cut easier.

Make sure the blade is at the right height to cut. As a general rule, the blade should be one tooth taller than the thickness of the board being cut. After cutting the wood, don’t lean over to pick it up until the blade is completely still.

Step 4) Put the Board Up Against the Fence of the Table Saw:

A table saw can cut a big piece of plywood. To keep the table steady when it comes off the saw, use an exit table or a roller stand. The best edge of the plywood should be against the fence. To keep it against the fence during the cut, push the corner of the board into the fence.

Step 5) Give the Whole Sheet of the Board Some Support:

Wood that is very big can be heavy. Before you start cutting them on a table saw, make sure you can keep them flat. Use easels to hold the sheet down, or ask a friend to help you do it.

When you have supports for the whole sheet, you can keep the feed rate or speed at which you move the wood through the saw, steady.

A circle saw can also be used to cut big sheets of plywood into smaller pieces that are easier to work with.

Step 6) Cover the Cut Line with Packing Tape:

On both sides of your board, use a low-tack tape like painter’s tape. By doing this, the fibers in the plywood will stay in place, and the sides will not chip. When you’re done cutting, slowly peel off the tape so it doesn’t break.

Glue is put on the board before it is cut with a table saw. The tape is made stronger with fiberglass or aluminum. Its width must meet these standards: there must be 1.5 to 2 cm of space on both sides of the cutting line.

It is better to glue or paste the tape, pushing it down with a dry cloth to keep it from getting wrinkled.

Step 7) Cut the Board so That the Best Side is Facing Up:

Place the board on the table saw so that the smooth side is facing up. The teeth on the table saw will go into the blade from the top and come out of it from the bottom. Where teeth come out, wood chips can happen, so keep your best face up.

Step 8) Use a Table Saw to Start Cutting the Board:

Keep the blade still and press down hard against the guide, which is the table saw’s straight edge. To move the board through the blade, use both hands.

To begin, push the board forward through the blade with the hand that is closest to it. As you move your hand away from the blade, push the board toward the line where you want to cut it.

Moving your hands around so that one is on each side of the blade as the cut gets closer will help you finish it. With care, feed the last bit of foil through the blade. When you use the table saw, be careful. Do not touch the blade with your hands.

Hold the board up with a roller stand as it goes through the cut. Put the roller bracket just below the board so that it is level. Make sure that the roller bracket is in the right place to hold the board up while it is being pulled apart.

After cutting the wood, don’t lean over to pick it up until the blade is completely still.

Tools for Cutting Plywood:

Table Saw:

The plywood can be cut correctly with a table saw that has a sharp wood blade.

However, the 4-by-8-foot (1.21-by-2.43-meter) blade and ¾-inch (1.90-centimeter) plywood that weighs 70 to 100 pounds (31 to 45 kilograms) make the table saw hard to move.

To hold the blade as it moves across the table supports and extension boards are placed around the saw.

Cut a rectangular hole in a board to make a piece that is the same size and can be mounted. This makes a unique plinth for plywood and sheets.

Circular Saw:

The blade that comes with a hand-held circular saw can also cut board.

Usually, the plywood blade is set up on two trestles that are next to each other, and the saw’s guide follows the line that was already drawn on the wood.

Vertical Plate Saw:

The vertical plate saw is another type of saw. Like the circle saw, it has a frame that holds the wood and a guide that goes through it.

This saw doesn’t take up much room and can make a full cut with little room.

On the other hand, it only has rough cuts and gets poked a lot.

Some vertical panel saws have cutting tools that can be switched out, like a floating router, a sheer insert laminate, a floating saw, and a razor.

Router:

Cutting the board is easy with a router that has a straight part, an experimental part, and a ruler.

The plywood widths are the same as the part sizes, and the skirting board finishes can also be used.

Methods for Cutting Plywood without Splintering with a Table Saw:

A table saw can be used to cut hardwood without making it split. Here are some tips that will help you cut plywood in a good way:

Step 1: Pick the Right Blade and Know how to Use it Right.

It shouldn’t be a surprise that the blade that comes with your circle saw, miter saw, or table saw won’t cut the way you want it to. For rough cuts in construction-grade softwood, these blades will work. But if you want to use them on hardwoods and other blade goods, you will need to get new ones.

For circle saws, get a plywood-cutting carbide-tipped blade that costs $15 to $20. Get an 80 TPI plywood blade for your table saw or miter saw. The blade should be made for cross cuts (miter saw) or ripping (table saw).

Step 2: There is No Clearance.

A zero-clearance insert is the best way to cut the board without breaking it. This fills in the hole in the throat plate or shoe around the blade. You can buy an aftermarket blank part for a table saw, or it’s easy to make your own.

Put a thin piece of plywood or hardboard that has been squeezed into the saw shoe of your circular saw. Then, lower the blade to make a free scratch groove.

The idea behind this method is to keep the space between the pressure plate and the blade base as small as possible. This keeps the top piece of plywood from coming off. Putting a cover plate on the tool sole will give you this look.

The pad has a slot that lets you cut along the line you want. This makes sure that the teeth will only cut small pieces of board and not break it.

Step 3: Put on Sticky Tapes:

Along the cutting line, tape is glued to cover the back of the plywood. This method works especially well if you choose to use an electric or hand jigsaw because it keeps big pieces from breaking off.

But not all kinds of sticky tape can be used for this. Masking tape, for instance, will not help at all in this situation because there is not much room for error.

Step 4: Make the Blade Taller.

Set the blade so that it comes out of the plywood right in the throat, which is the valley between the teeth.

This will keep the power tool from kickback. By lifting the blade, you can change the way that the teeth cut into the plywood. This lets you go from cutting at an angle to cutting almost straight down.

How to Use a Table Saw to Cut Board Without Making it Splinter:

- Cutting plywood sheets on the floor with full support.

- The cutting depth needs to be changed, which can affect the quality of the cut.

- In the long direction of the cut, a long, straight object is used to help guide the blade.

- Check the guide before you cut.

- They said to cut at a high speed, and that shouldn’t be changed.

- When you use a table saw to cut, you need to choose the blade with the most teeth.

- Sticky tape should be used to make the cross-cut.

Safety Considerations When Cutting Plywood with a Table Saw:

- Long sleeves, coats, neckties, and other loose clothing should be taken off or made tighter.

- You shouldn’t wear gloves when you use a table saw. Also, take off any rings, bands, or other jewelry that could get caught in the material or table saw.

- Wear safety glasses and earplugs made for working with a table saw.

- When you change the saw blade, make sure the blade arbor nut is tight.

- Lift the saw blade no more than 1/4 inch above the thing you’re cutting.

- Do not take out any small pieces from the saw until the blade has stopped moving.

- Stay behind or too close to the moving blade at all times to avoid getting hurt if it kicks back. There is no way to stop kickback because it is so dangerous.

- Check that the saw’s teeth are facing the right way to turn. The table saw should be used in a clockwise manner.

- Don’t let the off-cut pinch and shoot back at you. Always keep it on the side that doesn’t have the fence.

Ways to Make Sure You Cut Plywood Right on a Table Saw:

- The miter fence on a table saw can help you make cuts that are perfectly straight because it can be used both parallel to and perpendicular to the blade. This is a much better way to move the wood than using your hands.

- Since the rip fence stays aligned to the blade, the edges are always straight.

- Use a blade that is sharp and has the right number of teeth. It takes longer to cut with more teeth, but the cuts are better. Cutting with big teeth is faster, but the cuts are rough.

Bottom Line: How to Crosscut Plywood on a Table Saw

To summarise, all you need to do to make a crosscut in plywood using a table saw is to align your miter gauge, set the saw and board, and then make sure that your board is level and that it is pressed up against the fence as you cut.

Keep in mind that rough cuts are your best friend and that the rip cut, the miter cut, and the crosscut can all be made on your table saw with equal ease.

FAQs

Why Does Cutting Board Chip When You’re Done?

Putting a strip of masking tape across the cut line on both the top and bottom of the sheet will also keep it from breaking and splintering. Make sure you always use the right blade for plywood and that it is sharp. Make sure the smooth side of your board is facing up. The table saw cuts anticlockwise, which will leave splinters on the side it comes out of.

Can a Table Saw Cut the Board in Half Across?

You can cross-cut the board on a table saw if you have the right blade. Cross-cutting hardwood blades with 80 TPI should be used.

Related Posts: